FusionX

FUSIONX Overview

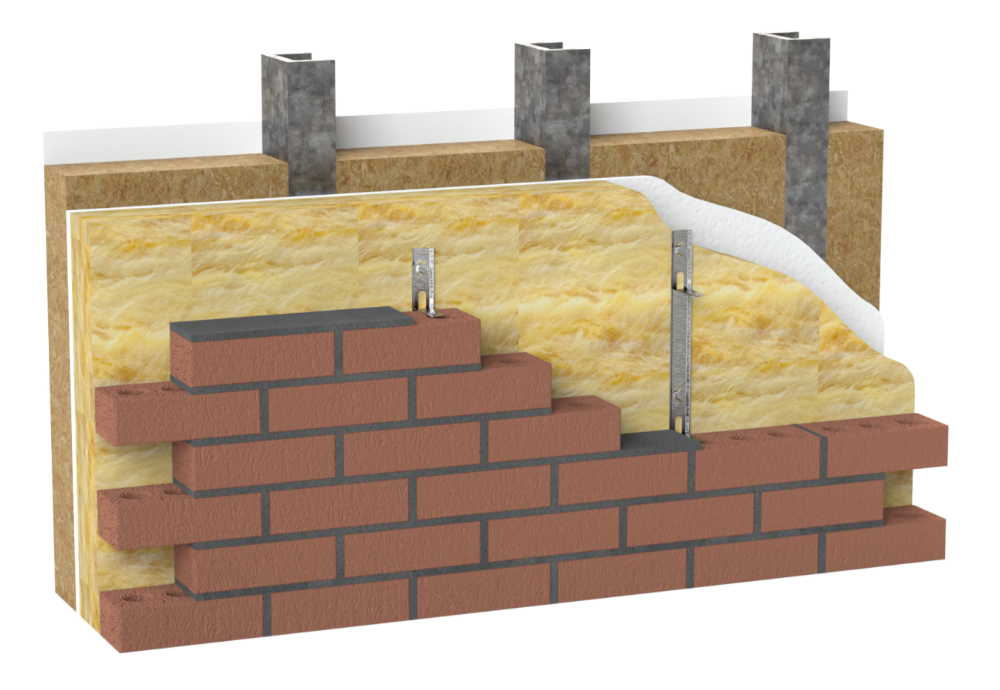

FUSIONX™ is a fully tested non-combustible walling solution which we developed in response to Building Regulation changes. Approved by the NHBC, FusionX™ holds LABC Warranty and is BOPAS accredited. This loadbearing external walling system is SCI and NHBC certified up to 10 storeys and can form part of a structure up to 14 storeys.

Fire

Enhancing onsite productivity through maximised Pre-Manufactured Value (PMV), FusionX™ is factory assembled for fast, cost-effective and quality-assured construction. FusionX™ has been tested thoroughly as an integrated system for thermal performance with fire resistance durations of 60, 90 and 120 minutes predictably achievable.

Thermal

Precision manufactured for rapid installation, FusionX™ can achieve U-values of 0.20W/m2k. The system provides developers and investors with a solution that offers a better strength to weight ratio than concrete, minimising groundworks and aiding sustainability outputs.*

*Refers to the fire-tested build-up.

Commercial

Commercial benefits include easier installation, enhanced on-site productivity and increased construction speed. FusionX™ is designed to be durable with a dimensionally stable material – steel has no risk of shrinkage, rotting, warping or cracking, and it does not expand or contract with moisture content. It is also renowned for being highly sustainable.

Technical data

Tried, tested and NHBC Approved with LABC Warranty, and BOPAS Accreditation – technical details for the FusionX™ offsite system are listed below, or you can download information from our downloads section.

Building height

- 10 Storeys of loadbearing frame and within a loadbearing structure up to 14 storeys

Stud

- Studs are 89mm. Overall wall is 92mm maximum, 600mm centres to form structural panels

Wall thickness

- (0.20W/m2K U-value, masonry wall)

- 354mm (excluding plasterboard)

Insulation in stud zone

- Mineral wool A1/A2

- Minimum density of 20kg/m3

- Tested solution Isover Steel Frame Infill Batt (20kg/m3)

- Specified, supplied and fitted by others, on site to manufacturer’s details

Insulation on cavity side

- Minimum of 100mm of rock mineral wool

- Minimum density 45kg/m3

- Rainscreen type, suitable for use in cavity with LGS frame

- Tested solution 100mm Polterm Max Plus (50kg/m3)

- Retained by at least steel washer per slab (see manufacturer guidance)

- Specified, supplied and fitted by others, on site to manufacturer’s details

Wall ties

- Stainless steel channel with sliding ties

- Channels must be fixed to studs, not sheathing board

- Screw sheathing sleeves may be required, depending on wall tie manufacturer

- Specified, supplied and fitted by others, on site to manufacturer’s details

Cladding support

- Typically helping hand brackets or cladding rails directly fixed to studs

- Specified, supplied and fitted by others, on site to manufacturer’s details

Cavity barriers

- Must be fitted back to sheathing board

- Specified, supplied and fitted by others, on site to manufacturer’s details

Fire from outside

- 100mm stone mineral wool plus sheathing board provides >120 minutes

- Tested solution 100mm Polterm Max Plus, in front of 12mm Y-wall sheathing board

Fire from inside

- Plasterboard to suit Fusion tested/assessed solutions as above